Valve insulation has evolved from skilled labor intensive methods to simpler rigid prefabricated jackets to even simpler and less expensive but effective solutions. Here’s a look at the evolution and the pros and cons of each type:

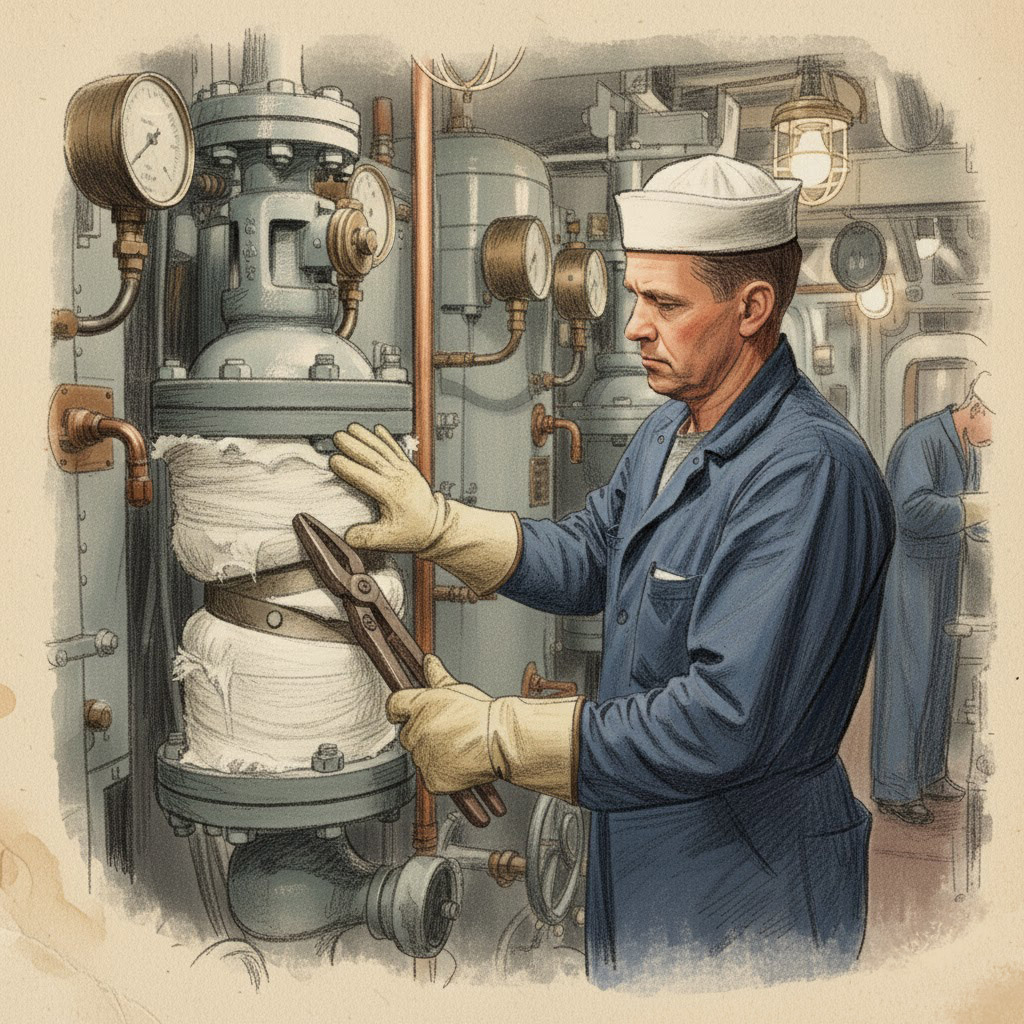

Custom Insulation On-Site

In the past, insulation was often created on-site using materials like fiberglass or mineral wool, wrapped and secured around the valve. An advantage to this method is that it can be adapted to fit complex valve shapes and sizes. Potentially lower material cost if using readily available materials. Custom on-site insulation is Labor-intensive and time-consuming. The quality can vary depending on the skill of the installer. It is typically hard to remove and reinstall for valve maintenance.Achieving a consistent level of insulation and quality of work depends on the installer.

The naval origin of reusable valve wraps

The need for accessible components on naval and civilian ships in the mid-20th century spurred the development of removable and reusable insulation blankets. The engine and steam systems on these ships required regular inspection and repair, which made single-use insulation impractical.

This reusable concept was eventually adopted more broadly in industrial settings, where complex pipe systems and valves also require regular maintenance.

Traditional Hard Valve Insulating Jackets

Pre-formed, rigid insulation jackets made of materials like fiberglass or calcium silicate have advantages like more consistent insulation performance than on-site fabrication, they are easier to install than on-site fabricated insulation, are durable and provide good protection for the valve. However, they can be difficult to remove and reinstall, requiring specialized tools. Fit is inflexible and limited to specific valve types and sizes, and they can be damaged during removal or installation.

Flexible Valve Insulating Jackets

Jackets made from flexible materials like silicone-coated fiberglass or high-temperature fabrics with a layer of insulating material inside are easier to install and remove than hard jackets. They can fit a wider range of valve sizes and shapes and offer good insulation performance. They are typically not as durable as hard jackets and can be more expensive than traditional insulation.

Reusable Valve Wraps

Newer, innovative wraps made from high-performance materials, designed for repeated use. Reusable Valve Wraps are the most economical and least labor intensive valve insulation option. They are extremely easy to install and remove with hook and loop fasteners. Tend to be durable and long-lasting, can be reused multiple times, reducing waste and cost and offer excellent insulation performance. Reusable Valve Wraps are not recommended for outdoor use

In Summary

The evolution of valve insulation has focused on improving ease of installation, reusability, and performance. While custom on-site insulation and traditional hard jackets still have some applications, flexible jackets and reusable wraps are becoming increasingly popular due to their versatility and convenience. The best choice for valve insulation will depend on the specific needs of the application, including the type of valve and frequency of maintenance.